KENANN DESIGN FEATURES

- Kenann penstocks are fabricated with stainless steel grade 304/316, duplex and super-duplex material.

- True bi-directional operation with no “on/off” seat pressure differential restrictions that allows for positive shut-off in either direction for fabricated penstock.

- Kenann penstocks use compression sealing for drip-tight shut off using polyurethane or synthetics rubber seal which eliminates grit and fines seat wear common in metal seated cast iron penstocks.

- Low friction operation using UHMWPE (Ultra -High Molecular Weight Polyethylene) guides which take up lateral loads.

- Penstocks are light weight with simple installation method.

- Unlimited custom-built options for unequal width & height requirements, including material composition.

- Standard flush bottom design eliminates debris build up.

- Reduced operating torque.

- Design head up to 50m head.

KENANN ATTRIBUTES

- Kenann fabricated penstocks, being compression sealed are not affected by “ON” or “OFF” seating force.

- Flat back mounting using chemical anchors & expanding grout with proper setting up off the levelling nuts on the mounting bolts eliminates frame twist.

- Where the operating mechanism is located remote from the unit, further consideration will need to be given to a floor stand & a headstock to support the floor stand.

- Our frames use stainless steel angle, channel sections or a mixture reinforced with fillets if necessary.

- Stainless steel plate is ribbed, if necessary, to meet pressure requirements. HDPE gate is reinforced with stainless steel rib.

- With stainless steel material, the steel property allows penstocks to be highly resistant to corrosion and erosion.

- Polyurethane, NBR, EPDM or Hypalon mould on extrusion can be reinforced with stainless steel wire as an option. One-piece sealing is applied on both edges & bottom of the gate. All seals offer minimum co-efficient of friction.

PENSTOCK SPECIFICATION

GENERAL

Each penstock shall be of the flush invert, rising stem design. However, we can also design and fabricate non-rising designs and T-key operation according to client’s needs.

All penstocks shall have frames and gates of stainless-steel construction.

All assembly bolts, nuts and washers shall be stainless-steel grade.

All components of the penstocks and actuators are designed such that no parts thereof will be stressed beyond their safe working limits.

FRAMES

Frames shall be of rigid construction to resist all loads reasonably expected to be encountered in service for the life of the penstocks. Frames shall be suitably reinforced and provided with corner and/or side gussets where necessary.

Wall-mounted penstocks shall have frames suitable for bolting direct to concrete structures. Sealing between the frames and concrete structures will be achieved by grouting. Channel-mounted penstocks will be cast into rebates in the concrete walls.

Frames shall provide a guide rail, along which the gate slides to fully open and close unobstructed and shall be of a length sufficient to support at least one-half of the gate in the fully opened position. Design of the guide rail shall be such that it is self-cleaning and clogging is minimal.

For wall mounted penstocks, the bolts securing the penstocks to the wall shall not impose any loads on the gate.

Flush bottom closure design shall incorporate a resilient seal securely contained at the invert of the frame to preclude loosening in service. The seal shall provide a flat plane across the bottom of the gate without projections into the opening to obstruct flow.

Stainless steel gates shall be made up of a single piece except for larger sizes where a two (2) piece composition is required, whereby the gates will be joined by means of welding.

Gates will be adequately ribbed when necessary to resist in-service loads. Sliding surfaces that come into contact with the seat facings shall be accurately machined.

The gate shall be of sufficient strength to withstand the maximum unbalanced head without deflection or distortion that would affect the operation of the penstock or reduce the water tightness.

Stems shall be of ample cross section to prevent buckling or permanent distortion under all operating conditions. The threads of the stem shall be machined out ACME type, ¼ pitch, single start and anti-clockwise closing.

Rising stems shall be provided with stops to prevent over-travel of the gate in either direction.

Drive nuts shall be machined from gunmetal (LG2) or bronze unless otherwise specified.

On rising stem penstocks, the drive nut shall be threaded and keyed or threaded and pinned to the stem. On non-rising stem penstocks, the drive nut shall be threaded but not keyed or pinned to the stem so that the nut gate can move up the stem as the stem turns.

SEALING

Frames shall be fitted with moulded, synthetic rubber, EPDM (70A durometer) or double density polyurethane seats with wire reinforcing (optional).

Seats shall be in one piece and provide continuous contact with the gate along the bottom and sides of the frame.

Seats shall be held in position by Ultra-High Molecular Weight Polyethylene.

(UHMWPE) retainers attached to the gate guides at bottom of the frame, with stainless-steel bolts and nuts.

Retainers shall be fitted to both sides of the moulded seat sections. Retainers fitted to the gate guides shall be machined to a smooth surface and positioned to minimize transverse gate movement and provide a low friction surface to carry gate loads.

HAND WHEEL

Hand wheels may be fabricated or cast in mild steel, stainless steel or cast iron. Castings shall be free from laminations and fins.

EXTENSION SPINDLES

Extension spindles and wall brackets shall be fabricated from stainless steel material.

Shafts shall be of sufficient interval diameter to provide adequate stem clearance.

Wall brackets shall have UHMWPE stem guides to suit the extension spindle.

Brackets shall be spaced so that the maximum unguided length of the extension spindle is between 1.5m and 2.5m.

PEDESTALS / HEADSTOCKS

Where pedestals, commonly known as headstocks are required, they shall be suitable for bolting onto concrete floors and shall rigidly support the actuator or hand wheel. Each pedestal shall be of such height that the horizontal axis of the hand wheel, both in the case of hand wheel operated penstocks and actuated penstocks, is approximately 900mm above the operating level, which corresponds to the base of the pedestal.

By default, hand wheel operated pedestals are fabricated at a height of 900mm while actuated or gearbox operated pedestals are at 800mm total height

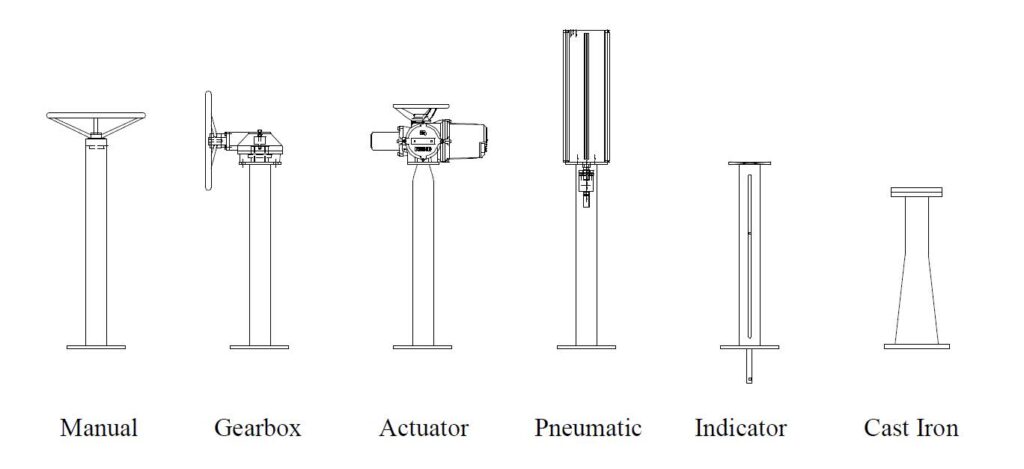

AVAILABLE PEDESTAL / HEADSTOCK CONFIGURATION

Our series of KENANN Penstocks are made to accommodate a variety of headstocks with different operator types, ranging from our standard manual operators using hand wheel to gearbox, electric actuator, pneumatic actuator, and custom-made bare shaft headstocks complete with optional level indicator. The headstock base plate (mounting plate) is machined to fit all ISO flange standards, and also custom fit sizes based on customer requirements.

As default, these headstocks are fabricated from mild steel but are also available in mild steel epoxy coating, galvanized mild steel, stainless steel, and cast iron upon request.

Please refer to the table below for the available options:

FLOORSTAND

In the event where the site structural works does not provide for headstock installation, a floor-stand (headstock mounting bracket) can be used to provide support to the headstock. Our standard floor-stands are fabricated using mild steel, complete with standard black paint finishing.

PENSTOCKS ASSEMBLY

KENANN HDPE & STAINLESS STEEL PENSTOCK

Stainless Steel Penstock

Stainless steel frame and gate. Available in SS304, SS316, duplex and super duplex. Wall mounted or channel mounted.

Stainless Steel Flange Penstock

Stainless steel frame and gate. Available in SS304, SS316, duplex and super duplex. Wall mounted or channel mounted.

KENANN HDPE FLAP GATE

Working Characteristics

- Superior Chemical & UV Resistance.

- Impact Resistance & No Material Fatigue.

- Due to comparatively Light Weight, no tedious and clumsy installation. Ease Maintenance & Servicing.

- Withstand wide fluctuation in temperature of pH of liquid medium

- Comparatively less opening pressure required.

- High ND and Reliable Seating with effective dimensional stability

- Reducing the chances of vandalism

Typical Applications

- Water Supply and Water Intake System

- Water Circulating System

- Irrigation and Removal of Storm Water

- Power & Refinery Plant

Construction & Material

- Flap Body –at least 30 mm thickness HDPE

- Gate Sealing – EPDM

- Hinges & Axis – stainless steel 304

- 7 degree incline to vertical

- Thickness of 20mm, 30mm or 40mm

Depend on the size of gate - By Fusion Welding

- Reinforce with HDPE pipe

- Inner hinge bush is Bronze material

- Back frame comes with replacement EPDM rubber seal

- Manufactured in Malaysia

Scope of Application

To regulate water flow in single direction pattern and prevent back flow during high water level occurrence or flood

General Properties:

- Melting Temperature – above 135 co

- Distortion Temperature – above 150 co

- Density = 0.95 g/cm3

- Linear Expansion Coefficient – above 200.

- Tensile Strength – 15 – 30 N/m3.

- Elongation Breaking Ratio – above 900

- Withstanding Back Pressure of up to 15 feet

Size

From 300 – 3500 mm in Circular, Square, Rectangular In Black Color